Expert Amada Turret Punch Press Sleeving & Rebuilding Services

All Sleeves are Made in the USA and will never be outsourced

Comprehensive Sleeving Solutions for Amada Turret Punch Presses

When your Amada Turret Punch Press shows signs of wear, it can lead to inefficiencies, increased downtime, and costly repairs. Our specialized sleeving services are designed to restore your equipment to optimal performance, ensuring precision, longevity, and reliable operation.

Why Choose Sleeving for Your Amada Turret Punch Press?

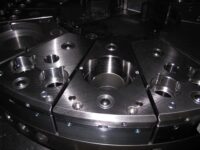

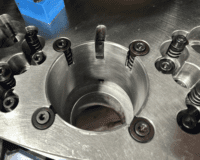

Sleeving is a crucial process that restores the precision and functionality of your turret punch press. Over time, the turrets on these machines can wear down, leading to misalignment and inaccuracies during operation. Our sleeving process involves installing new sleeves into the worn turret bores, restoring them to their original specifications. This not only extends the life of your equipment but also enhances its performance.

Benefits of Turret Sleeving:

- Restored Precision: Sleeving eliminates the wear and tear on the turret bores, bringing them back to factory specifications.

- Extended Machine Life: By addressing the worn components, sleeving extends the operational life of your Amada Turret Punch Press.

- Cost-Effective: Sleeving is a more affordable alternative to replacing the entire turret, offering a cost-effective solution to maintain machine performance.

- Minimized Downtime: Our efficient process ensures that your machine is back in operation quickly, reducing production interruptions.

High-Quality Repair and Rebuilding Services

In addition to sleeving, we offer a full range of repair and rebuilding services for Amada Turret Punch Presses. Whether your machine requires minor repairs or a complete overhaul, our team of experienced technicians is equipped to handle all aspects of the rebuild process.

Complete Turret Rebuilds

A complete turret rebuild involves disassembling the turret, inspecting all components for wear, and replacing or refurbishing parts as necessary. Our rebuild services are designed to restore your turret punch press to like-new condition, ensuring reliable and accurate performance.

Key Features of Our Rebuilding Services:

- Thorough Inspection: Every component is carefully examined to identify wear or damage.

- Precision Machining: We use advanced machining techniques to restore components to their original specifications.

- Quality Parts: Only high-quality replacement parts are used to ensure durability and performance.

- Testing and Calibration: After rebuilding, each machine undergoes rigorous testing and calibration to ensure it meets industry standards.

Specialized Repair Services

If your Amada Turret Punch Press is experiencing specific issues, we offer targeted repair services to address them. Our team is skilled in diagnosing and repairing a wide range of problems, from alignment issues to hydraulic malfunctions.

Common Repair Services Include:

- Turret Realignment: Misalignment can cause significant issues in punch accuracy and tool life. We realign the turret to restore precision.

- Hydraulic System Repair: Hydraulic issues can lead to inconsistent punching force. Our experts can diagnose and repair these systems to ensure consistent operation.

- Control System Upgrades: Outdated control systems can limit the efficiency of your machine. We offer upgrades to modernize your equipment, improving functionality and ease of use.

Industry-Leading Expertise in Amada Machine Tool Services

With years of experience in the industry, our team has developed a deep understanding of Amada Turret Punch Presses. We are dedicated to providing the highest quality services to keep your machines running smoothly and efficiently.

Certified Technicians with Specialized Training

Our technicians undergo rigorous training and certification programs to stay current with the latest techniques and technologies in the industry. This ensures that they are fully equipped to handle any repair, rebuild, or sleeving job with the highest level of expertise.

Commitment to Quality and Customer Satisfaction

We are committed to delivering the best possible service to our customers. From the initial consultation to the completion of the job, we strive to exceed your expectations at every step. Our goal is to build long-term relationships with our clients by providing reliable, high-quality services that meet their needs.

Our Quality Assurance Process:

- Detailed Assessments: We begin with a comprehensive assessment of your machine to identify all issues.

- Clear Communication: We keep you informed throughout the process, providing updates and recommendations as needed.

- Post-Service Support: After the service is complete, we offer ongoing support to ensure your machine continues to operate at its best.

Custom Solutions Tailored to Your Needs

Every manufacturing environment is unique, and we understand that one-size-fits-all solutions don’t always work. That’s why we offer custom solutions tailored to the specific needs of your operation.

Flexible Service Options

We offer a range of service options to fit your schedule and budget. Whether you need a quick repair to get your machine back online or a complete rebuild to extend its life, we have a solution that fits.

Service Packages Include:

- Preventative Maintenance Programs: Regular maintenance is key to avoiding costly downtime. Our preventative maintenance programs are designed to keep your Amada Turret Punch Press in top condition.

- Emergency Repair Services: When unexpected issues arise, our emergency repair services are available to get you back up and running as quickly as possible.

- Scheduled Rebuilds: Plan ahead with scheduled rebuilds to ensure your machine remains reliable and efficient.

Customized Upgrades and Enhancements

In addition to repairs and rebuilding, we offer a range of upgrades and enhancements to improve the performance of your Amada Turret Punch Press. Whether you’re looking to increase speed, improve accuracy, or reduce maintenance costs, we can help you achieve your goals.

Popular Upgrades Include:

- Control System Modernization: Upgrade to a modern control system for improved functionality and ease of use.

- Enhanced Tooling Options: Expand your machine’s capabilities with advanced tooling options designed for specific applications.

- Energy-Efficient Upgrades: Reduce energy consumption and operating costs with our energy-efficient upgrade options.

Reliable Partner for Your Amada Turret Punch Press Needs

Choosing the right partner for your Amada Turret Punch Press maintenance and repair needs is crucial to ensuring the long-term success of your operation. With our industry-leading expertise, commitment to quality, and custom solutions, we are the reliable partner you can trust.

Proven Track Record of Success

We have a proven track record of delivering high-quality services to a wide range of clients in the manufacturing industry. Our satisfied customers attest to our ability to deliver results that meet or exceed expectations.

Testimonials from Satisfied Customers

John D., Manufacturing Manager:

“We had been experiencing issues with our Amada Turret Punch Press for months. After engaging their sleeving services, the machine is running like new. The team was professional, knowledgeable, and completed the job on time. Highly recommend!”

Sarah M., Operations Director:

“The complete rebuild of our turret punch press was handled with exceptional care and attention to detail. The machine’s performance has significantly improved, and we couldn’t be happier with the service provided.”

Contact Us for Expert Amada Turret Punch Press Services

If your Amada Turret Punch Press is in need of repair, rebuilding, or sleeving, don’t wait until the issues worsen. Contact us today to discuss your needs and find out how we can help you keep your operations running smoothly.

Get a Free Consultation

We offer a free consultation to assess the condition of your machine and provide you with a detailed quote for the services required. Our team is ready to answer any questions you may have and help you find the best solution for your specific needs.

How to Reach Us:

- Phone: 1-888-884-2447

- Website: Amada Turret Punch Press Sleeving and Repair Services

Don’t let equipment wear and tear slow down your production. Trust our expert team to restore your Amada Turret Punch Press to its peak performance.